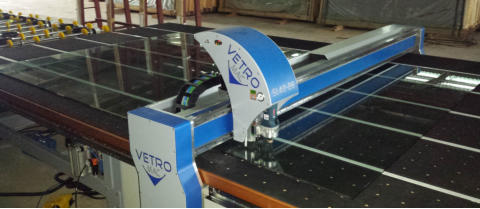

HIGH PERFORMANCE AND AFFORDABLE GLASS MACHINERY

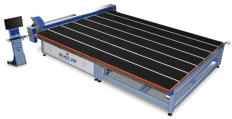

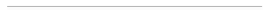

Max. workable glass sheet mm. 4000 x 2600 (157” x 102”).

Also available in SL42-26 (165” x 102”) and SL42-28 (165” x 110”)

Workable thickness From 2 to 19 mm (1/16 to 3/4 in). Machine can cut every kind of glass (except tempered)

Equipped with:

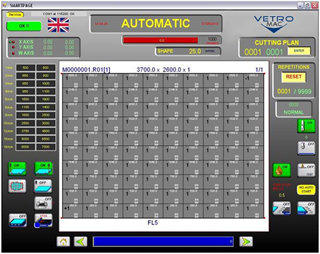

Control panel with incorporated independent Computer WiFi

and 21" Touch Screen , software packet with optimization

program developed in Multitasking systems with 250

parametric preconstructed shapes, user graphic interface for

the managing of the cutting cycle and machine monitoring ,

security systems following the laws, handbook in English..

Safety of the glass presence:

A sensor is placed on the cutting head, to stop the machine in

case of lack of glass sheets

Management of mechanisms:

Immediate and controlled braking of the bridge and the

cutting head, as soon as an emergency occurs.

Weight Kg. 2200 (4850 lbs)

Work surface height: Adjstable from 890 to 960 mm (34.65 to

38.19 in)

Maximum installed power Kw 8

Performance:

Maximum speed of the bridge and cutting head 180 m/min (590 ft/min)

Max. acceleration 0.8 sec. from 0 to max. speed

Max. deceleration 0.8 sec. From max. speed to 0

Accuracy:

Max. difference in length between two diagonals for an area bigger than 2mq (21.528 sq.ft.) (glass 3 mm thick) (1.118 in.) +/-0.20 mm (0.0196 in)

Rectilinearity tolerance (glass 3 mm thick) (1.118 in.) +/- 0.15 mm (straight cutting) +/-0.20 mm ( shape cutting).

Sliding systems:

Sliding systems of the bridge are a rack and

pinion system. The racks and the pinions are

tempered and re-machined for greater

accuracy and decreased wear over time.

They have a ± 0.02 mm tolerance over a 1.20

mt (47.24 in) length. The teeth on the racks

are installed upside down to keep dust and

dirt out.

A pinion is placed on either side of the bridge

(two in all), to always keep the bridge

perpendicular to the cutting table during the

acceleration and deceleration phases of cutting.

On linear guide and rack are applied to both sides of the table, to obtain a

overall bridge stability during the entire cutting cycle.

Cutting Bridge

The cutting bridge is made

of rigid Steel. The whole

system is very stable and

insensitive to temperature

changes, assuring a

minimum wear and tear.

Cutting trolley is made from

aluminium.

The cutting head is made

with special machines with

hundredth tolerances.

Going up and down system of the cutting head is guided by a system

with re-circulation of ball-bearings, to reduce the friction as much as

possible and guarantee the cutting head responds to glass sinkings.

Glass sheet squaring:

The alignment of glass sheet is

automatic trought laser 3Directions.

Work surface Made in very hard

wood, covered with woollen felt of

high density and compactness, 4

mm thick (0.157 in).

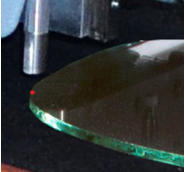

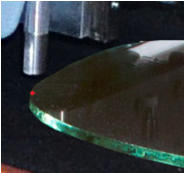

Laser scanning (Optional Included):

Laser System for copying of the

shapes, of any material, with

double control of the correct survey

of the points.

User Interface:

Multitasking systems, control of three

interpolated axles, easy-to-use, with icons and

buttons of the relevant command, with Computer

WiFi and 21" Touch Screen.

Optimisation program: PerfectCut Optimization

software. Includes a 250 parametric shapes

library, import/export data.

Max. workable glass sheet mm. 3700 x 2600 (145” x 102”).

Workable thickness From 2 to 19 mm (1/16 to 3/4 in). Machine can cut every kind of glass (except tempered)

Equipped with:

Control panel with incorporated independent Computer WiFi and 21" Touch Screen , software packet with optimization

program developed in Multitasking systems with 250 parametric preconstructed shapes, user graphic interface for the

managing of the cutting cycle and machine monitoring , hydraulic tilting surface, air cushion, ventilator for the movement

of the sheet on the surface, , double zero for the cutting of laminated glass, security systems following the laws,handbook

in English.

Safety of the glass presence:

A sensor is placed on the cutting head, to stop the machine in case of lack of glass sheets

Management of mechanisms:

Immediate and controlled braking of the bridge and the cutting head, as soon as an emergency occurs.

Weight Kg. 2200 (4850 lb)

Work surface height:

Adjstable from 890 to 960 mm (34.65 to 38.19 in)

Maximum installed power Kw 10

Performance:

Maximum speed of the bridge and cutting head 180 m/min (590

ft/min)

Max. acceleration 0.8 sec. from 0 to max. speed

Max. deceleration 0.8 sec. From max. speed to 0

Accuracy:

Max. difference in length between two diagonals for an area bigger

than 2m sq (21.528 sq.ft.) (3 mm thick) (1.118 in.) +/-0.20 mm

(0.0196 in)

Rectilinearity tolerance (glass 3 mm thick) (1.118 in.) +/- 0.15 mm

(straight cutting) +/-0.20 mm ( shape cutting).

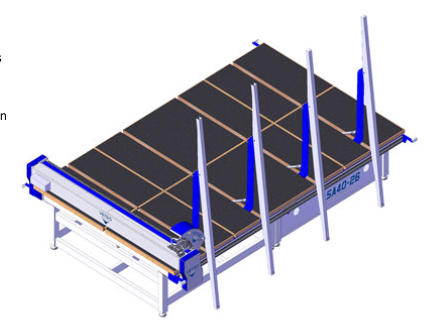

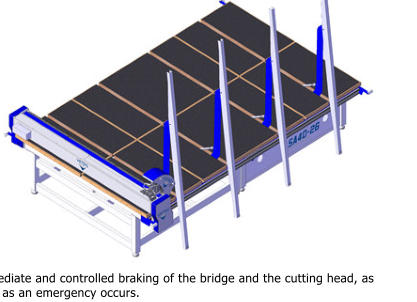

CNC Shape Glass Cutting - Stand Alone with Air floatation

Max. workable glass sheet mm. 4000 x 2600 (157” x 102”) - Fantastic Value

Also available in Models: SA42-28 (165” x 110”) and SA26-19 (102” x 75”).

Workable thickness From 2 to 19 mm (1/16 to 3/4 in). Machine can cut every kind of glass (except tempered)

Equipped with:

Control panel with incorporated independent Computer WiFi and 21" Touch Screen , software packet with optimization

program developed in Multitasking systems with 250 parametric preconstructed shapes, user graphic interface for the

managing of the cutting cycle and machine monitoring , hydraulic tilting surface, air cushion, ventilator for the

movement of the sheet on the surface, , double zero for the cutting of laminated

glass, security systems following the laws,handbook in English.

Safety of the glass presence:

A sensor is placed on the cutting head, to stop the machine in case of lack of glass

sheets

Management of mechanisms:

Immediate and controlled braking of the bridge and the cutting head, as soon as an

emergency occurs.

Weight Kg. 2200 (4850 lb)

Work surface height:

Adjstable from 890 to 960 mm (34.65 to 38.19 in)

Maximum installed power Kw 10

Performance:

Maximum speed of the bridge and cutting head 180 m/min (590 ft/min)

Max. acceleration 0.8 sec. from 0 to max. speed

Max. deceleration 0.8 sec. From max. speed to 0

Accuracy:

Max. difference in length between two diagonals for an area bigger than 2m sq

(21.528 sq.ft.) (3 mm thick) (1.118 in.) +/-0.20 mm (0.0196 in)

Rectilinearity tolerance (glass 3 mm thick) (1.118 in.) +/- 0.15 mm (straight cutting) +/-0.20 mm ( shape cutting).

Max. workable glass sheet mm. 6100 x 3300 (240” x 130”).

Workable thickness From 2 to 19 mm (1/16 to 3/4 in). Machine can cut every kind of glass (except tempered).

Equipped with:

Control panel with incorporated independent Industrial Computer WiFi and 21" Touch Screen , software packet with optimization

program developed in Multitasking systems with 250 parametric preconstructed shapes, user graphic interface for the managing

of the cutting cycle and machine monitoring , security

systems following the laws, handbook in English..

Safety of the glass presence:

A sensor is placed on the cutting head, to stop the

machine in case of lack of glass sheets

Management of mechanisms:

Immediate and controlled braking of the bridge and the

cutting head, as soon as an emergency occurs.

Weight Kg. 3000 (6614 lb)

Work surface height: Adjstable from 890 to 960 mm (34.65

to 38.19 in)

Maximum installed power Kw 12

Performance:

Maximum speed of the bridge and cutting head 180 m/min

(590 ft/min)

Max. acceleration 0.8 sec. from 0 to max. speed

Max. deceleration 0.8 sec. From max. speed to 0

Accuracy:

Max. difference in length between two diagonals for an area bigger than 2mq (21.528 sq.ft.) (glass 3 mm thick) (1.118 in.) +/-0.20 mm (0.0196 in)

Rectilinearity tolerance (glass 3 mm thick) (1.118 in.) +/- 0.15 mm (straight cutting) +/-0.20 mm ( shape cutting).

Why Buy Vetromac? Great features, build quality and support at a good price!

CNC Shape Glass Cutting - Stand Alone with Air floatation

CNC Shape Glass Cutting - Stand Alone with Air floatation

High Production CNC Shape Glass Cutting -Fixed Tops with Belt Transport (Require Loading and Breakout Table)

Layout ST37-26

Layout SA26-19

Layout SA40-26

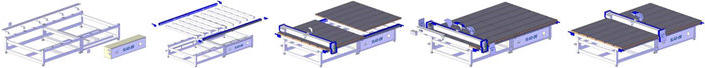

New Concept of Production and Assembly

We have developed a new concept of building machines. Every single part of the machine is designed with 3D CAD technology, processed by CAD CAM

and machined with CNC Working Center.

This innovative system is the only one that can guarantee perfect uniformity and constant quality of all the machines that are being built and allows every

single part of the machine to be easily replaced if needed, even the felt table surface.

Machine assembly is divided into specific steps, controlled by a management software chart, which supports and guides our technicians during the various

stages of assembly, the following picture is an example of the assembly steps:

V

Layout SL40-26

Layout SL42-26

Layout SL42-28

Made in Italy

CNC Shape Glass Cutting - Stand Alone with Air floatation

Manual Glass Cutting Tables - Made in Canada - To Order

Manual Glass Cutting Tables

Well designed and made.

Solid tubular metal frame construction.

Common sizes: Glass sheets up to

130” x 96”

145” x 102”

(Other size available upon request)

Popular options include:

- Air Floatation (standard or for glass 3/8” or thicker)

- Tilting Top (Manual with counter-balance or Pneumatic)

- Breaker Bars (manual or pneumatic)

Heavy Duty Steel Structure to ensure long life and stability. Various sizes and models available

Heavy Duty Steel Structure to ensure long life and stability. Various sizes and models available

Cutting line layout examples

Layout SL60-33

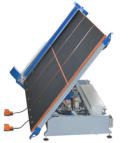

Model ST37-26 (Tilting Top with Air Floatation)

Model SA40-26 (Fixed Top with Air Floatation and Loading Arms)

Serving Canada and USA since 2008

Over 30 years of Glass fabricating experience

CONTACT US

T: +1-416-342-7547

F: +1-905-492-2230

Toll Free:

F: 1-888-222-6339

PRODUCTS

© 2015 Atwood Sales Inc. All rights reserved.

Model SL40-26 (Fixed Top with Belt Transport)

Model SL60-33 (Fixed Top with Belt Transport)

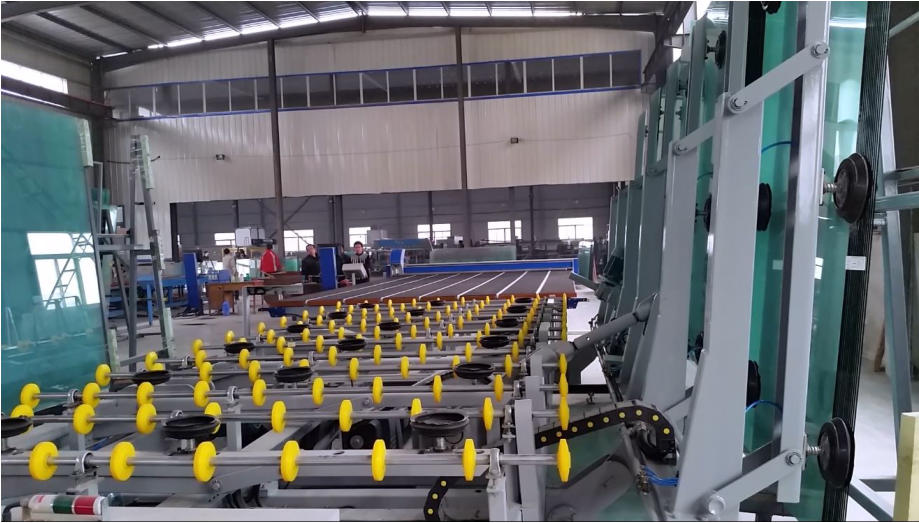

Automatic Glass Loader

Glass Breakout Tables

Premium Italian Glass Cutting Tables at an affordable price!

HIGH PERFORMANCE AND AFFORDABLE GLASS MACHINERY

Max. workable glass sheet mm. 4000 x 2600 (157” x 102”).

Also available in SL42-26 (165” x 102”) and SL42-28 (165” x 110”)

Workable thickness From 2 to 19 mm (1/16 to 3/4 in).

Machine can cut every kind of glass (except tempered)

Equipped with:

Control panel with incorporated independent Computer

WiFi and 21" Touch Screen , software packet with optimization program

developed in Multitasking systems with 250 parametric preconstructed

shapes, user graphic interface for the managing of the cutting cycle and

machine monitoring , security systems following the laws, handbook in

English..

Safety of the glass presence:

A sensor is placed on the cutting head, to stop the machine in case of lack of

glass sheets

Management of mechanisms:

Immediate and controlled braking of the bridge and the cutting head, as

soon as an emergency occurs.

Weight Kg. 2200 (4850 lbs)

Work surface height: Adjstable from 890 to 960 mm (34.65 to 38.19 in)

Maximum installed power Kw 8

Performance:

Maximum speed of the bridge and cutting head 180 m/min (590 ft/min)

Max. acceleration 0.8 sec. from 0 to max. speed

Max. deceleration 0.8 sec. From max. speed to 0

Accuracy:

Max. difference in length between two diagonals for an area bigger than

2mq (21.528 sq.ft.) (glass 3 mm thick) (1.118 in.) +/-0.20 mm (0.0196 in)

Rectilinearity tolerance (glass 3 mm thick) (1.118 in.) +/- 0.15 mm (straight

cutting) +/-0.20 mm ( shape cutting).

Sliding systems:

Sliding systems of the bridge are a rack and

pinion system. The racks and the pinions are

tempered and re-machined for greater

accuracy and decreased wear over time.

They have a ± 0.02 mm tolerance over a 1.20

mt (47.24 in) length. The teeth on the racks

are installed upside down to keep dust and

dirt out.

A pinion is placed on either side of the bridge

(two in all), to always keep the bridge

perpendicular to the cutting table during the

acceleration and deceleration phases of cutting.

On linear guide and rack are applied to both sides of the table, to obtain a

overall bridge stability during the entire cutting cycle.

Cutting Bridge

The cutting bridge is made

of rigid Steel. The whole

system is very stable and

insensitive to temperature

changes, assuring a

minimum wear and tear.

Cutting trolley is made from

aluminium.

The cutting head is made

with special machines with

hundredth tolerances. Going

up and down system of the cutting head is guided by a system with re-

circulation of ball-bearings, to reduce the friction as much as possible

and guarantee the cutting head responds to glass sinkings.

Glass sheet squaring:

The alignment of glass sheet is

automatic trought laser 3Directions.

Work surface Made in very hard wood,

covered with woollen felt of high

density and compactness, 4 mm thick

(0.157 in).

Laser scanning (Optional Included):

Laser System for copying of the

shapes, of any material, with double

control of the correct survey of the

points.

User Interface:

Multitasking systems, control of three interpolated

axles, easy-to-use, with icons and buttons of the

relevant command, with Computer WiFi and 21"

Touch Screen.

Optimisation program: PerfectCut Optimization

software. Includes a 250 parametric shapes library,

import/export data.

Max. workable glass sheet mm. 3700 x 2600 (145” x 102”).

Workable thickness From 2 to 19 mm (1/16 to 3/4 in). Machine can cut

every kind of glass (except tempered)

Equipped with:

Control panel with incorporated independent

Computer WiFi and 21" Touch Screen , software

packet with optimization program developed in

Multitasking systems with 250 parametric

preconstructed shapes, user graphic interface for the

managing of the cutting cycle and machine monitoring , hydraulic

tilting surface, air cushion, ventilator for the

movement of the sheet on the surface, , double

zero for the cutting of laminated glass, security

systems following the laws,handbook in English.

Safety of the glass presence:

A sensor is placed on the cutting head, to stop

the machine in case of lack of glass sheets

Management of mechanisms:

Immediate and controlled braking of the bridge and the cutting head,

as soon as an emergency occurs.

Weight Kg. 2200 (4850 lb)

Work surface height:

Adjstable from 890 to 960 mm (34.65 to 38.19 in)

Maximum installed power Kw 10

Performance:

Maximum speed of the bridge and cutting head 180 m/min (590

ft/min)

Max. acceleration 0.8 sec. from 0 to max. speed

Max. deceleration 0.8 sec. From max. speed to 0

Accuracy:

Max. difference in length between two diagonals for an area bigger

than 2m sq (21.528 sq.ft.) (3 mm thick) (1.118 in.) +/-0.20 mm

(0.0196 in)

Rectilinearity tolerance (glass 3 mm thick) (1.118 in.) +/- 0.15 mm

(straight cutting) +/-0.20 mm ( shape cutting).

Max. workable glass sheet mm. 4000 x 2600 (157” x 102”) -

Fantastic Value

Also available in Models: SA42-28 (165” x 110”) and SA26-19 (102”

x 75”).

Workable thickness From 2 to 19 mm (1/16 to 3/4 in).

Machine can cut every kind of glass (except tempered)

Equipped with:

Control panel with incorporated independent Computer

WiFi and 21" Touch Screen , software packet with

optimization program developed in Multitasking systems

with 250 parametric preconstructed shapes, user graphic interface for the

managing of the cutting cycle and machine monitoring , hydraulic tilting

surface, air cushion, ventilator for the movement of the sheet on the

surface, , double zero for the cutting of laminated glass, security systems

following the laws,handbook in English.

Safety of the glass presence:

A sensor is placed on the cutting head, to stop the machine in case of lack

of glass sheets

Management of mechanisms:

Immediate and controlled braking of the bridge and the cutting head, as

soon as an emergency occurs.

Weight Kg. 2200 (4850 lb)

Work surface height:

Adjstable from 890 to 960 mm (34.65 to 38.19 in)

Maximum installed power Kw 10

Performance:

Maximum speed of the bridge and cutting head 180 m/min (590 ft/min)

Max. acceleration 0.8 sec. from 0 to max. speed

Max. deceleration 0.8 sec. From max. speed to 0

Accuracy:

Max. difference in length between two diagonals for an area bigger than 2m

sq (21.528 sq.ft.) (3 mm thick) (1.118 in.) +/-0.20 mm (0.0196 in)

Rectilinearity tolerance (glass 3 mm thick) (1.118 in.) +/- 0.15 mm (straight

cutting) +/-0.20 mm ( shape cutting).

Max. workable glass sheet mm. 6100 x 3300 (240” x 130”).

Workable thickness From 2 to 19 mm (1/16 to 3/4 in). Machine can cut

every kind of glass (except tempered).

Equipped with:

Control panel with incorporated independent Industrial

Computer WiFi and 21" Touch Screen , software packet

with optimization program developed in Multitasking

systems with 250 parametric preconstructed shapes, user

graphic interface for the managing of the cutting cycle and machine

monitoring , security systems following the laws, handbook in English..

Safety of the glass presence:

A sensor is placed on the cutting head, to stop the machine in case of lack

of glass sheets

Management of mechanisms:

Immediate and controlled braking of the bridge and the cutting head, as

soon as an emergency occurs.

Weight Kg. 3000 (6614 lb)

Work surface height: Adjstable from 890 to 960 mm (34.65 to 38.19 in)

Maximum installed power Kw 12

Performance:

Maximum speed of the bridge and cutting head 180 m/min (590 ft/min)

Max. acceleration 0.8 sec. from 0 to max. speed

Max. deceleration 0.8 sec. From max. speed to 0

Accuracy:

Max. difference in length between two diagonals for an area bigger than

2mq (21.528 sq.ft.) (glass 3 mm thick) (1.118 in.) +/-0.20 mm (0.0196 in)

Rectilinearity tolerance (glass 3 mm thick) (1.118 in.) +/- 0.15 mm (straight

cutting) +/-0.20 mm ( shape cutting).

Why Buy Vetromac? Great features,

build quality and support at a good

price!

CNC Shape Glass Cutting - Stand Alone with Air floatation

High Production CNC Shape Glass Cutting

Fixed Tops with Belt Transport (Require Loading and Breakout Table)

Layout ST37-26

Layout SA26-19

Layout SA40-26

New Concept of Production and Assembly

We have developed a new concept of building machines. Every single part

of the machine is designed with 3D CAD technology, processed by CAD

CAM and machined with CNC Working Center.

This innovative system is the only one that can guarantee perfect

uniformity and constant quality of all the machines that are being built

and allows every single part of the machine to be easily replaced if

needed, even the felt table surface.

Machine assembly is divided into specific steps, controlled by a

management software chart, which supports and guides our technicians

during the various stages of assembly, the following picture is an example

of the assembly steps:

V

Layout SL40-26

Layout SL42-26

Layout SL42-28

Made in Italy

CNC Shape Glass Cutting - Stand Alone with Air floatation

Heavy Duty Steel Structure to ensure long life and stability.

Various sizes and models available

Heavy Duty Steel Structure to ensure long life and stability.

Various sizes and models available

Cutting line layout examples

Layout SL60-33

Model ST37-26 (Tilting Top with Air Floatation)

Model SA40-26 (Fixed Top with Air Floatation and Loading Arms)

Model SL40-26 (Fixed Top with Belt Transport)

Model SL60-33 (Fixed Top with Belt Transport)

Automatic Glass Loader

Glass Breakout Tables

Premium Italian Glass Cutting Tables at an affordable price!

PRODUCTS

CONTACT US

T: +1-416-342-7547

F: +1-905-492-2230

Toll Free:

F: 1-888-222-6339

Serving Canada and

USA since 2008

Over 30 years of

Glass fabricating experience

Manual Glass Cutting Tables - Made in Canada - To Order

Manual Glass Cutting

Tables

Well designed and made.

Solid tubular metal frame

construction.

Common sizes: Glass sheets

up to

130” x 96”

145” x 102”

(Other size available upon

request)

Popular options include:

- Air Floatation (standard or

for glass 3/8” or thicker)

- Tilting Top (Manual with

counter-balance or

Pneumatic)

- Breaker Bars (manual or

pneumatic)